About the Project

ABOUT THE PROJECT

Sentient, an established technology provider to the mining industry, has introduced the services of specialists in the development of Internet of Things (IoT) solutions. Collaborating with a leading Australian-based mining equipment manufacturer, Sentient worked with the client to create an innovative early warning system. Driven by Narrowband Internet of Things (NBIoT) technology, the system aims to revolutionise hose maintenance by providing real-time information, allowing for early detection of wear and tear.

CHALLENGE:

An Australian mining equipment manufacturer faced the challenge of proactively identifying the wear and tear in rubber hoses, essential components in the industry’s operations. Traditional methods were either non-existent or both labour-intensive and costly, requiring a cost-effective and reliable solution.

The aim was to develop an early warning system that could operate on battery-power with a central monitoring platform to track the health of multiple hoses across diverse locations. This would make it easier to identify when a pipe was deteriorating so that a replacement could be planned, as opposed to waiting until the pipe was worn, potentially resulting in increased downtime and replacement expenses.

SOLUTION:

Sentient was able to deliver a comprehensive solution using NBIoT technology. This enabled the client to remotely detect the wear in pipes with a central web-based platform to monitor the health of the pipes.

The framework followed several key components:

Cutting-Edge 4G GPS Sensors: The systems 4G GPS sensors were purchased from a local supplier and are designed to monitor GPS location. These sensors, equipped with analogue and digital inputs, were used to monitor the wear and tear in the pipes and update on any changes in state. All sensors have built-in GPS trackers, which provide real-time location data, which is helpful for delivery and storage information.

Web-Based Platform: The web-based platform provides a central location for monitoring the health of multiple pipes. Using intuitive maps, the platform can pinpoint the location of the hoses, simultaneously relaying sensor data to indicate the health of the pipes. The platform also enables the client to perform remote configuration, empowering the user with the ability to adjust the sensor’s parameters by sending downlink commands via the web-based server.

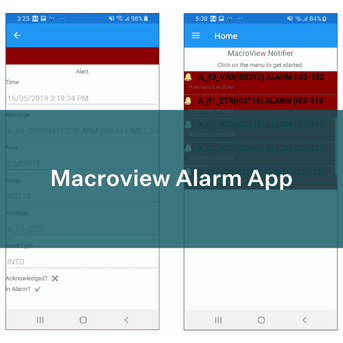

Instant Alerts: With safety principles in mind, timing is crucial. Sentient’s solution incorporates quick alert mechanisms. Through SMS and email-based notifications, the system promptly communicates detected wear and anomalies. This proactive approach allows users to act timely and mitigate potential risks and downtime.

OUTCOME:

Sentient’s solution has been successfully implemented. Data updates are received at desired intervals to optimise battery life. Clients now receive vital alerts, giving them the ability to preempt potential issues. The scalability of the system has also been proven, as additional sensors have been effortlessly integrated into the existing infrastructure. NBIoT technology’s reach into remote, communication-challenged areas highlights the use case for robust asset management. Sentient’s innovative solution empowers the client with an efficient early warning system and empowers users to take timely maintenance actions to prevent costly failures

Learn more about Sentient’s IoT solutions and discover how Sentient can help your next IOR project become a reality.