About the Project

ABOUT THE PROJECT

Sentient, an established technology provider to the mining industry, has partnered with specialists in Internet of Things (IoT) solutions to deliver innovative, data-driven monitoring systems. Collaborating with a leading Australian-based mining equipment manufacturer, Sentient helped design and implement an intelligent detection platform that leverages Narrowband Internet of Things (NBIoT) connectivity to collect and transmit critical operational data in real time.

The system is built to enhance visibility of key equipment conditions and environmental parameters, enabling early detection of anomalies and improving maintenance planning and operational efficiency across remote mining sites.

CHALLENGE:

An Australian mining equipment manufacturer required a reliable and cost-effective way to monitor machine performance and site conditions across multiple, geographically dispersed locations. Traditional approaches often relied on manual inspection or inconsistent reporting, which limited proactive decision-making and increased the risk of unplanned downtime.

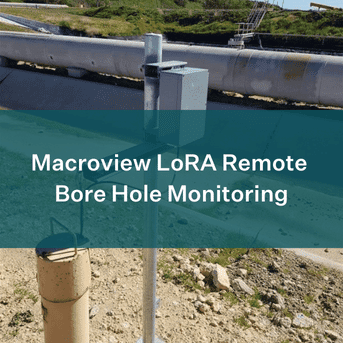

The goal was to create a low-power, autonomous monitoring network capable of collecting and transmitting data from various assets to a central platform. The solution needed to be scalable, battery-efficient, and capable of operating in harsh and connectivity-challenged mining environments.

SOLUTION:

Sentient delivered a comprehensive IoT framework built around NBIoT and Satellite communications technology, allowing real-time collection and transmission of field data to a secure, web-based platform.

Core Components:

Smart Sensors and Edge Devices:

Using ruggedised 4G/NBIoT/Satellite-enabled sensors sourced from local suppliers, the system captures analogue and digital signals from mining assets. These sensors provide configurable data inputs that can represent a wide range of field parameters—such as pressure, temperature, vibration, flow, or equipment state—and automatically relay this data to the cloud.

Web-Based Monitoring Platform:

A centralised web platform visualises and manages all deployed devices. Through intuitive mapping and dashboards, users can view asset status, historical trends, and sensor alerts. Remote configuration capabilities allow technicians to adjust thresholds and data transmission parameters directly from the platform via downlink commands.

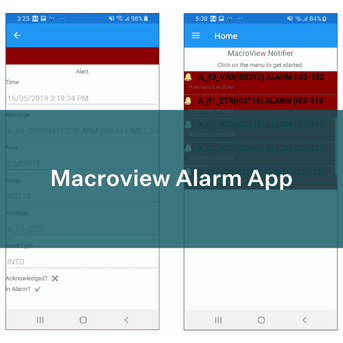

Automated Alerts and Notifications:

Built-in safety and maintenance principles drive the alerting system. When anomalies or out-of-range conditions are detected, users receive instant notifications via SMS or email, allowing for prompt corrective action to prevent potential failures or production interruptions.

OUTCOME:

The IoT-based detection system has been successfully deployed and proven across multiple field sites. Data transmission frequency and battery life have been optimised for mining conditions, and the system’s modular design has allowed new sensor types and data streams to be easily integrated.

By enabling continuous condition monitoring and early detection of potential issues, the client has reduced unplanned downtime and gained improved visibility of asset performance in remote operations. NBIoT and Satellite technology has demonstrated strong connectivity in challenging environments, validating its use for scalable, long-range IoT deployments in mining.

Sentient’s solution empowers mining clients to make data-driven maintenance decisions, enhance operational safety, and extend the life of critical assets.

Learn more about Sentient’s IoT capabilities and discover how we can help your next connected mining project become a reality.