About the Project

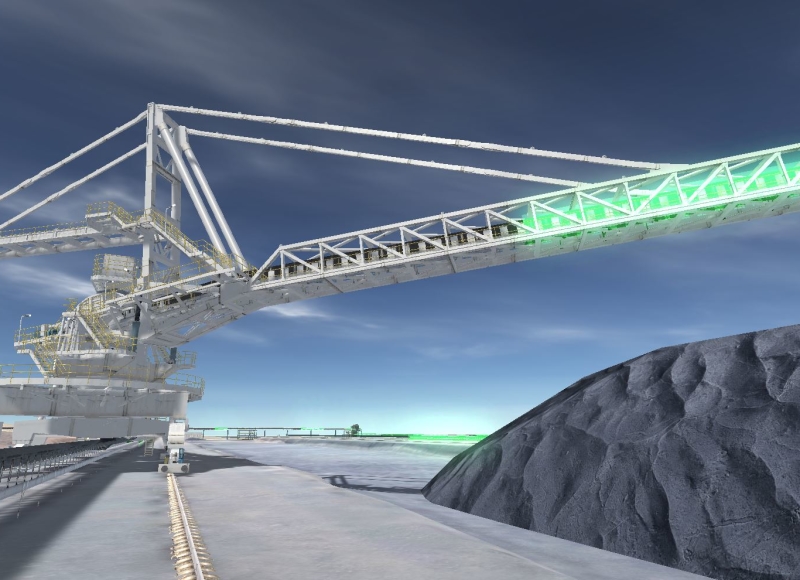

One of WA’s leading mining companies approached Sentient and requested us to provide an effective and low-cost wireless solution to monitor different levels of vibration across motors driving conveyors, pulleys, pumps and other rotary equipment onsite. Sentient proposed an (IoT) based solution to wirelessly transmit data from onsite assets to the main data centre and historian.

CHALLENGE:

- Install a secure wireless network and provide a longer range to cover a large area in order to monitor the equipment scattered onsite.

- The wireless technology must be cost effective by having inhouse data processing and storing capability rather than depending on a third-party cloud platform and associated ongoing costs.

- Source sensors which are not only compatible with the selected wireless technology but also hold an industry standard rating to be installed on a mine site.

- Sensors must be battery powered with limited power consumption and offer a long production time.

Provide a solution which is flexible enough so that other types of sensors can be integrated into the network in the future.

SOLUTION:

Sentient Computing provided a solution based on LoRa wireless technology which uses the LoRaWAN protocol to communicate on the 915MHz Australian frequency band.

- LoRa was used to provide wireless communication.

- A LoRaWAN compliant local Gateway was installed to provide secure in-house communication.

- LoRaWAN compliance Class A sensors with a battery life of {How many?}years and a sampling rate which can be configured to suit the application have been installed.

- The sensors have a magnetic base which can be easily attached to metallic surfaces without worrying about screws or bolts. This aides in maintenance of the units and battery charging when required.

- The processed data can be integrated with client’s backend data centre or historian.

- The sensors send raw data with each payload and vibration severity based on ISO 10816.

OUTCOME:

- The developed solution was tested and verified onsite before full installation.

- The sensors and gateway were successfully installed onsite. Sensors were chosen to not only match the technical requirements but also to physically fit the environment which proved to be pivotal point for the whole project.

- Data is decoded and processed to match the client’s requirements.

- This project also proved that LoRaWAN has plenty of applications in industrial internet of things and can be expanded to include more areas of industry.