About the Project

Offshore Installations are complex assets with hundreds, or even thousands, of components to maintain and monitor. In most locations, operators have developed control systems with simple graphical interfaces that report real time responses of the equipment, and technicians are charged with monitoring these data output streams. These systems bear little resemblance to the plant itself and, while they have greatly improved efficiency over physical inspection alone, they can be cumbersome to navigate and usually do not integrate with document libraries and other key information.

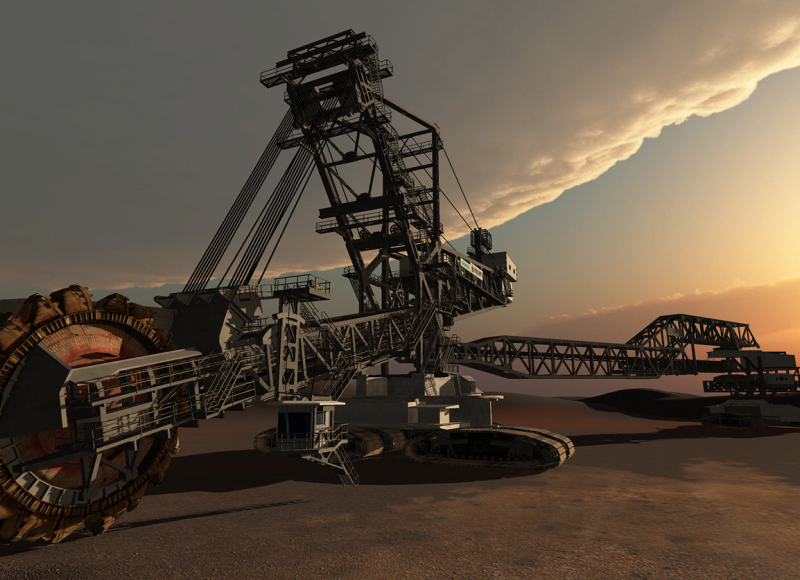

Sentient and Holis combined forces to change the way that our customer accessed their data, by creating a Digital Twin of the offshore asset using the customers’ existing infrastructure.

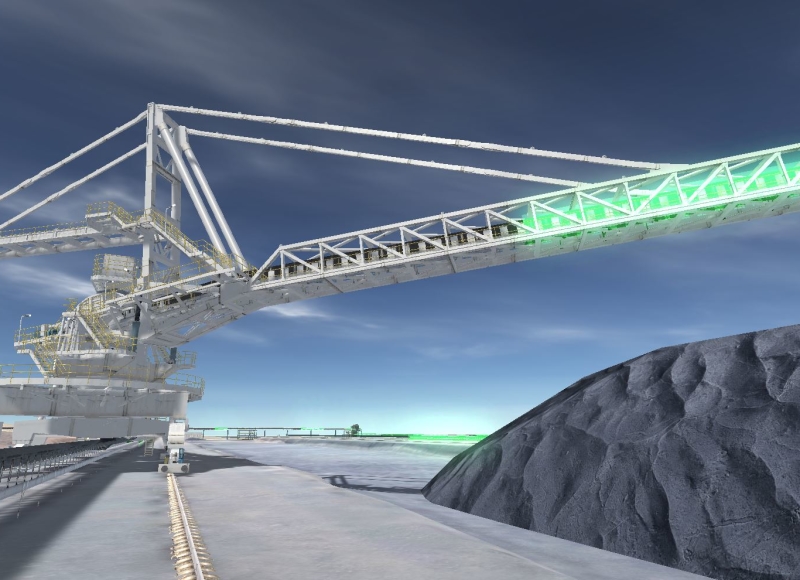

This Digital Twin was swiftly brought to an operational level using the Sentient Digital Asset Pipeline. The pipeline automatically processed heavy design models into selectable and taggable digital assets of scalable detail that can be easily navigated in a web application. Using the tagging system, the customer’s existing data streams were then tethered to the assets, along with maintenance histories and procedures sourced from a variety of different document management systems.

This working Digital Twin immediately improved on the customer’s ability to observe equipment with out of tolerance readings and click, filter or search to access relevant technical documents in a single application. Immediate efficiency gains could be reaped by operations and maintenance teams, as well as a reduction in the cost and exposure associated with having personnel on site.

Future development for this platform is exciting!

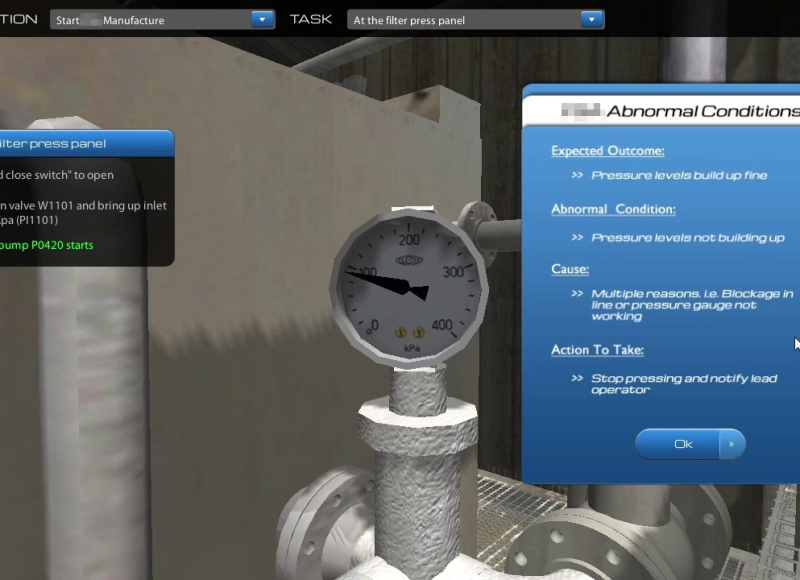

Since InDI was able to rapidly transform the customer’s monitoring system from an old GUI into a 3D Digital Twin environment without any additional physical hardware, our customer can experiment within the environment and make informed decisions on where new sensors will further advance their capacity to respond remotely. AR Support is being investigated, as well as the integration of VR training and procedures.

CHALLENGE:

- Current methods for monitoring a key offshore asset were unintuitive, and limited the customer’s ability to monitor assets remotely,

- This led to efficiency loss in identifying and correcting issues and an increase in the requirement for physical investigation at the site.

- Key information about the equipment on the installation is not centrally located so it takes time to locate and can be easily missed:

- Current Status

- Maintenance history

- Maintenance procedures

- Moving from an old platform to a new platform usually takes considerable immediate investment and a long setup and implementation phase, that makes change unappealing!

SENTIENT & HOLIS SOLUTION:

- Using the Sentient Digital Asset Pipeline and Unity3D, Sentient were able to use the customers existing data to immediately build an InDI Digital Twin.

- The flexible tagging system allowed Holis to connect data streams and document links from any number of locations to individual pieces of equipment.

- A full digital replica of the platform containing all the available equipment data was created that was intuitively navigable by a user through a web application.

- Intelligent filtering and customized overlays were created to further improve the user experience.

- With the Sentient Digital Twin, users are now able to rapidly identify faults and critical information about all equipment in a single platform.

FUTURE DEVELOPMENT:

- Using the initial product, the customer can extend their ability to make decisions remotely, by identifying where additional information will be helpful and adding sensors or cameras.

- The interoperability and asynchronous nature of the system allows for efficient and rapid incremental development and any new sensors can be seamlessly integrated into the existing InDI environment.

- Further scope for integrating Augmented Reality and 3D Virtual Reality procedures into the platform is being explored.