About the Project

CHALLENGE

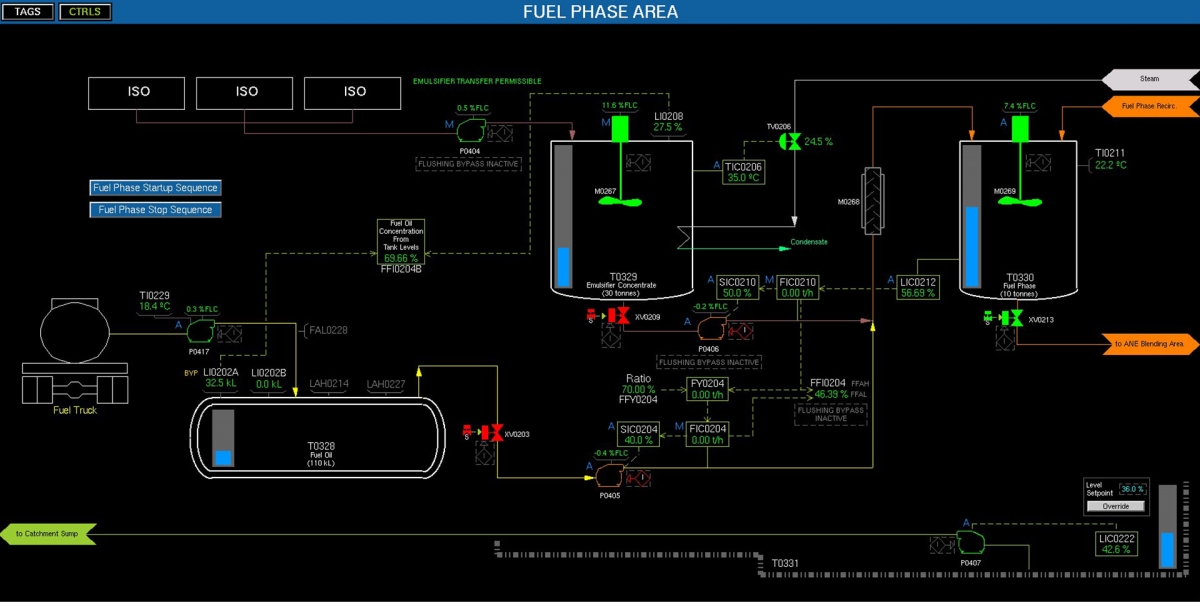

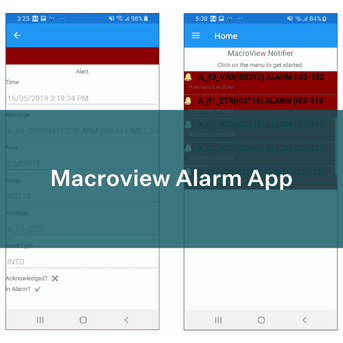

- Develop a complete process control HMI system for the operation and monitoring of the plant, including schematics, plant control sequences, diagnostics, and alarms

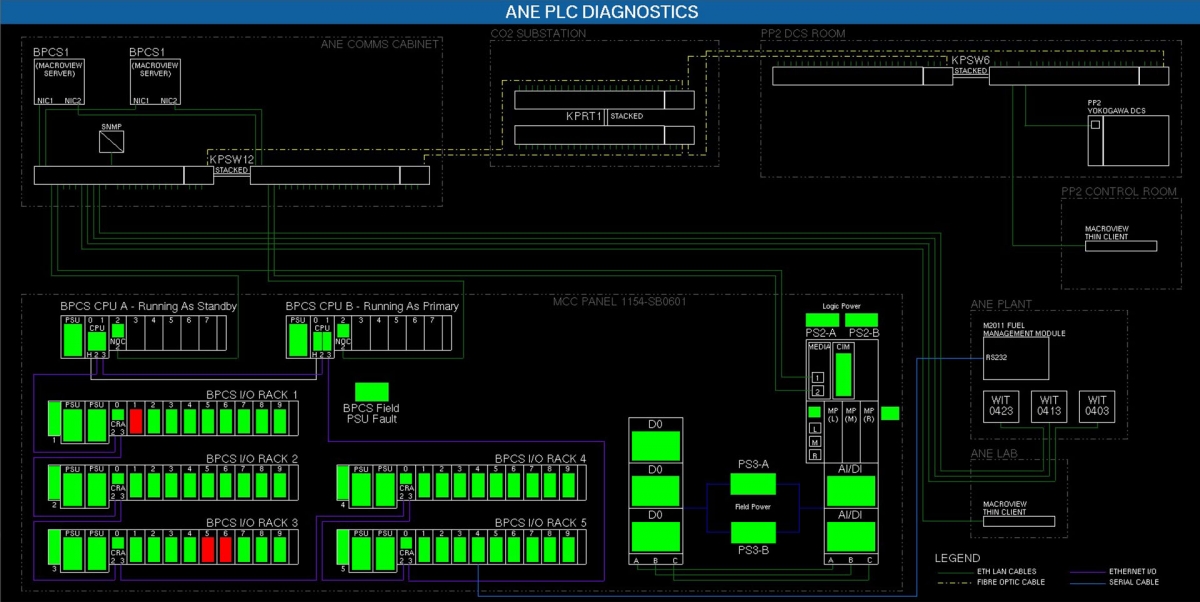

- Configure IO with the PLC and integrate with CSBP’s Customer Despatch System

- Create a complete set of dynamic trip and interlock diagrams for the plant

- Trend and historise plant data, and provide remote access and data extraction capabilities

- Supply, install, and configure hardware

- Provide remote support and regular backups of configuration and data.

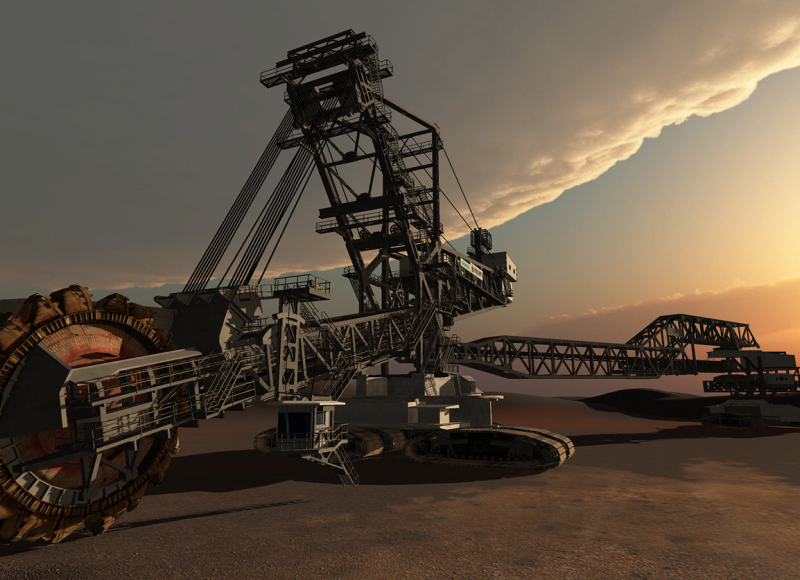

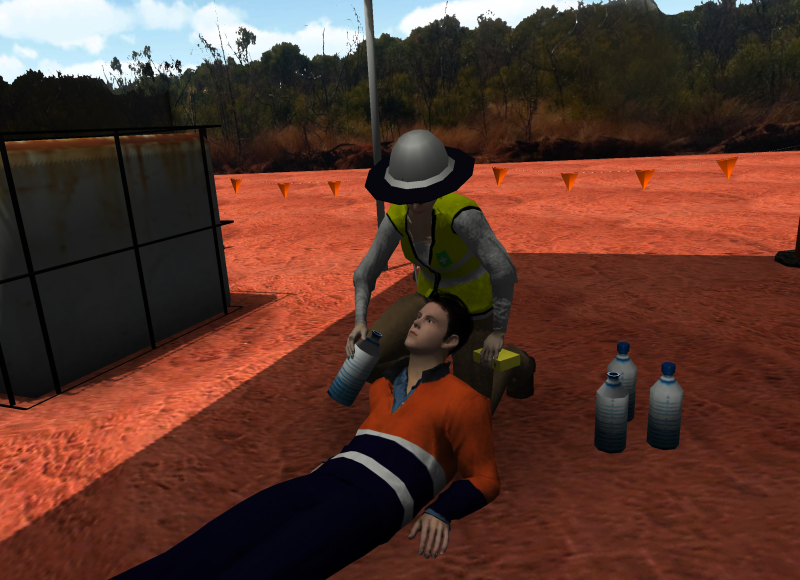

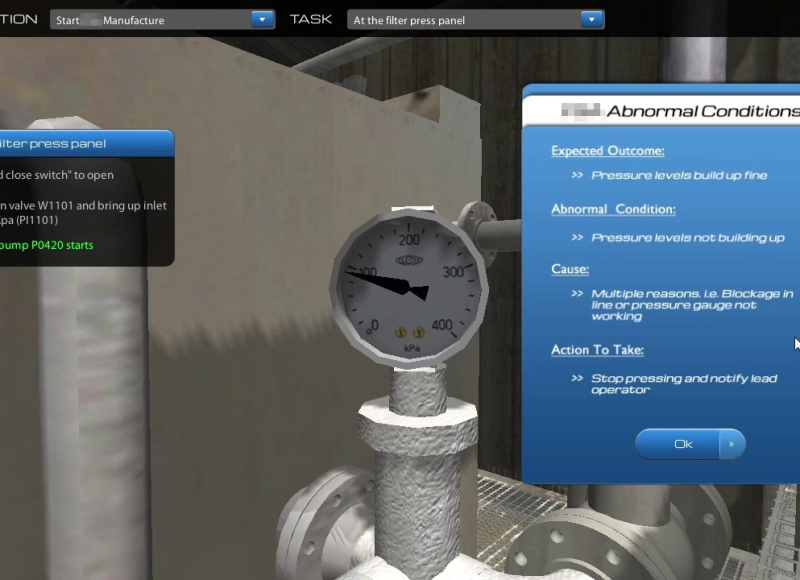

- Create an immersive and interactive 3D environment of the plant

- Develop both Virtual Reality and desktop computer navigation capabilities for the 3D environment

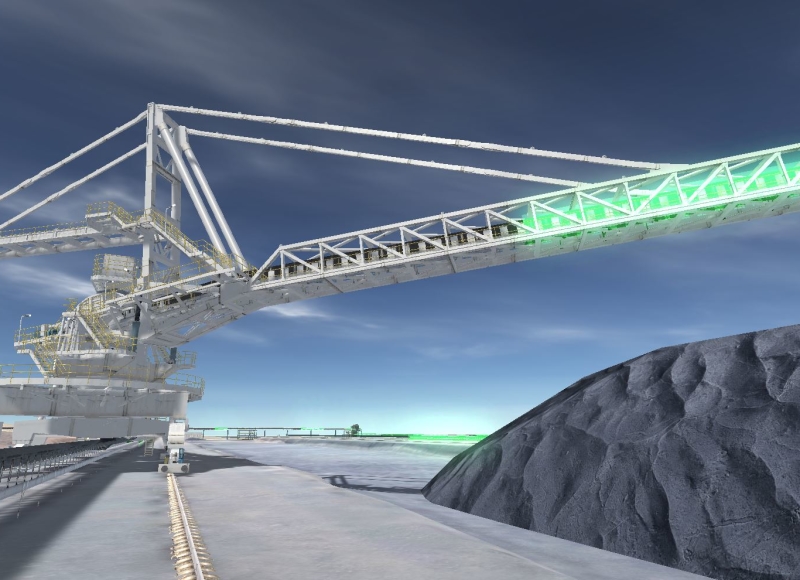

- Create a narrated flythrough video of the entire plant, detailing what each area of the plant does and how it works.

SOLUTION

- A MacroView process control solution was developed in close collaboration with the PLC programmers and the customer

- Sentient worked closely with CSBP’s IT and Networking teams to provide, install, and configure all hardware required, as well as to integrate MacroView into CSBP’s Customer Despatch System

- A complete set of digital trip and interlock diagrams were developed within MacroView, and dynamically linked to statuses and alarms from the PLC

- Over 1000 data points were trended and historised, and scheduled archiving and backups were configured according to the customer’s needs

- Sentient provided both on-site and remote support throughout the entire commissioning process of the plant.

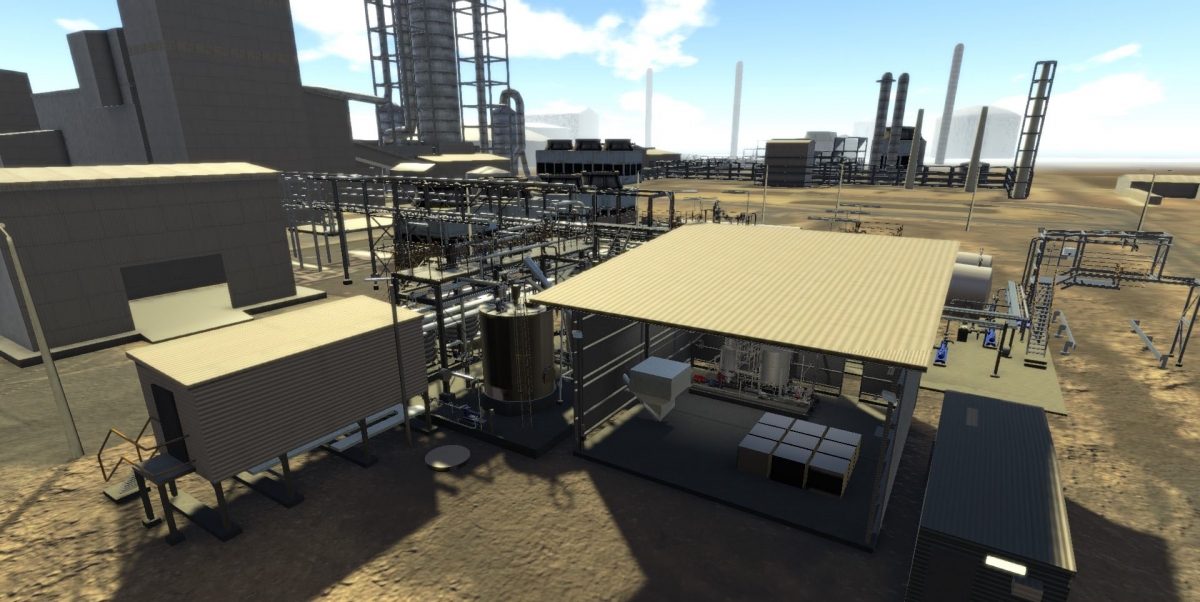

- A realistic and immersive 3D environment of the plant was developed and optimised to run in realtime

- Virtual Reality capabilities were added to the environment, allowing users to freely navigate and interact with the model in VR

- A flythrough video containing a detailed narration was created to show and explain the layout and workings of the plant.

OUTCOME

- The MacroView solution developed by Sentient provides every piece of functionality required by CSBP to operate and monitor the plant as effectively as possible

- Integration into CSBP’s network and Customer Despatch System provides easy accessibility to truck appointment and loading data

- CSBP’s engineers and operators continue to use the dynamic trip and interlock diagrams to identify the causes for plant trips, reasons for plant interlocks, and to operate the plant as efficiently as possible

- Trends provide a reliable means of monitoring the performance of the plant, and can be used to identify potential issues before they even occur

- The extensive and easily-accessible plant data provides a wide variety of reporting and analysis options to the customer

- Sentient continues to provide on-site, remote, and after-hours assistance as required by the customer.

- The interactive Virtual Reality environment provided operators and engineers the opportunity to visualise and traverse the plant well before it had been constructed

- The flythrough video provided a very informative breakdown of how the plant works and has been used for training and plant inductions.